Dry up to 10X FastER with Gas Catalytic Infrared

Lower cost, improved quality

For over thirty years, catalytic industrial systems has designed & built high efficiency industrial process heaters & ovens for manufacturers across the globe.

products

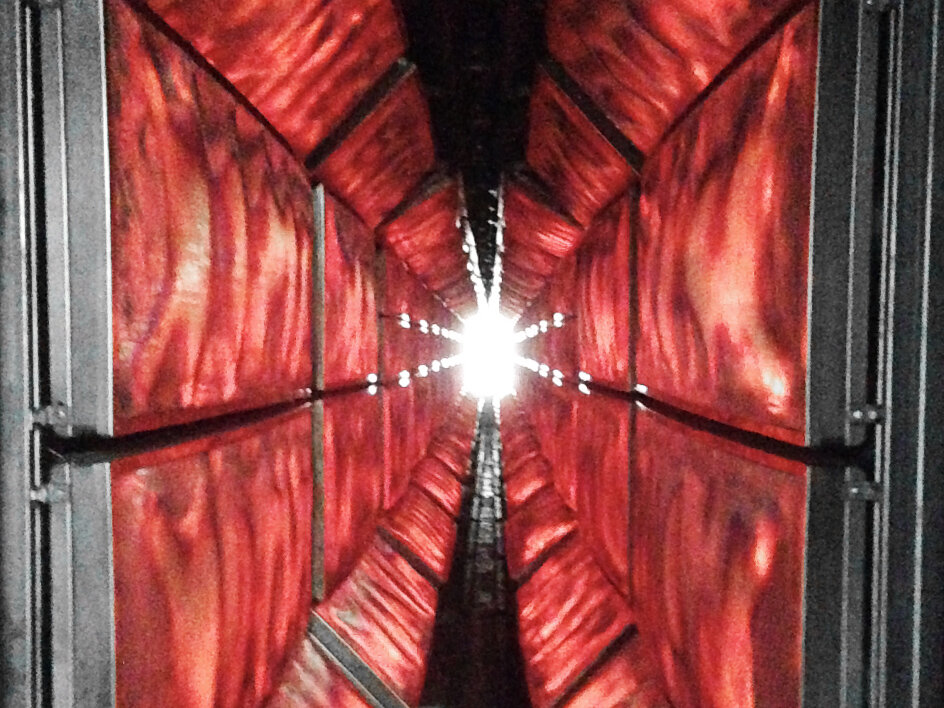

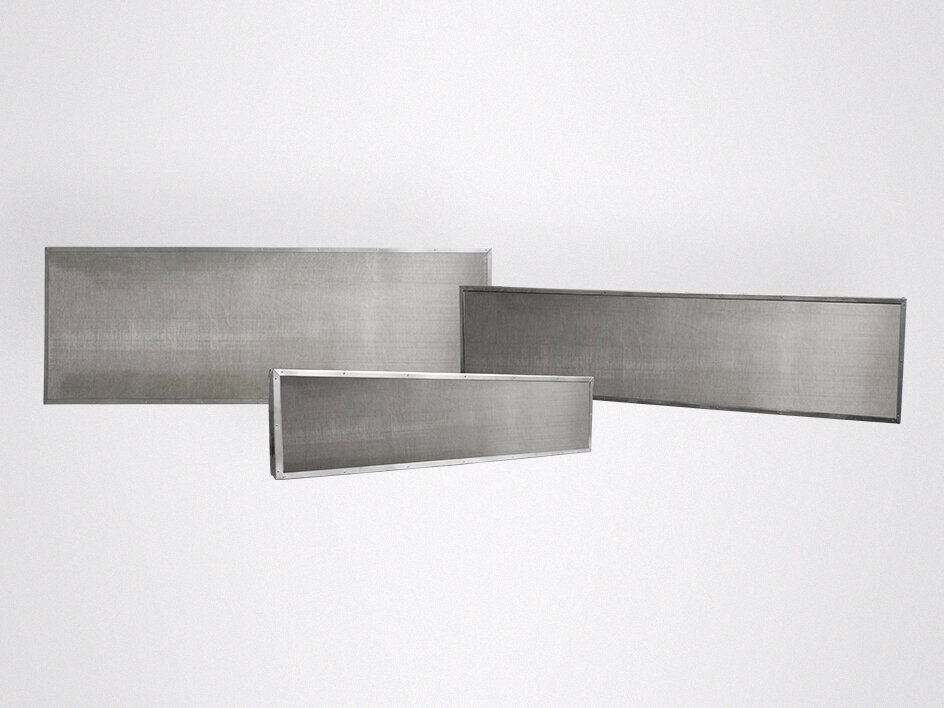

CIS offers gas catalytic infrared heating solutions that are high performing, energy efficient, and safe. At the heart of the system are gas catalytic infrared heaters offered in multiple sizes and duties configurable for optimal results and versatility.

Ovens & heating solutions are custom designed and manufactured to meet the needs of each customer & application. From heaters on racks for retrofits or field integration, batch ovens, or large scale conveyor ovens, CIS is ready to help.

In addition to the heaters, a complete oven includes microprocessor-based PLC with color HMI control panels, single or multi-zone gas trains, and the ventilation system that’s right for your application.

“Our facilities have specified CIS paint curing oven systems for over 20 years worldwide. They are smaller in size, reliable and energy efficient.

Gas infrared has helped improve production because the accelerated ramp-up technology rapidly brings the temperature of the part to optimum."

— Paint Manager- World's leading manufacturer of construction, mining equipment and engines

applications

Industrial Manufacturers with liquid or powder coating processes utilize CIS gas catalytic infrared heating system for the substantial savings in process time, reduced energy costs and increased production capacity. From wind turbine blades to consumer razors, infrared gas catalytic heaters are utilized worldwide by manufacturers with paint curing needs. CIS gas catalytic IR ovens consistently outperform convection oven systems by as much as 80%.

Gas Catalytic Infrared

CIS catalytic heaters emit heat in the form of FAR infrared energy. FAR is a long wavelength infrared energy, more readily absorbed by most materials than the shorter wave infrared energy others use. Heat goes right to the coating or paint, for faster curing, reduced process times by up to 80%, and lower operating costs.